Products

Coalescence system separator

1. Type of technology

Physical principle of coalescence.

2. Contaminants which can be removed

Mists and vapours of lubricating oil, cooling oil, inks, asphalt, DOP. Emissions from plastic and textile processes, etc.

3. Emission limits possible

Emission limits should be examined case-by-case; it is possible to reach collection efficiencies over 90%.

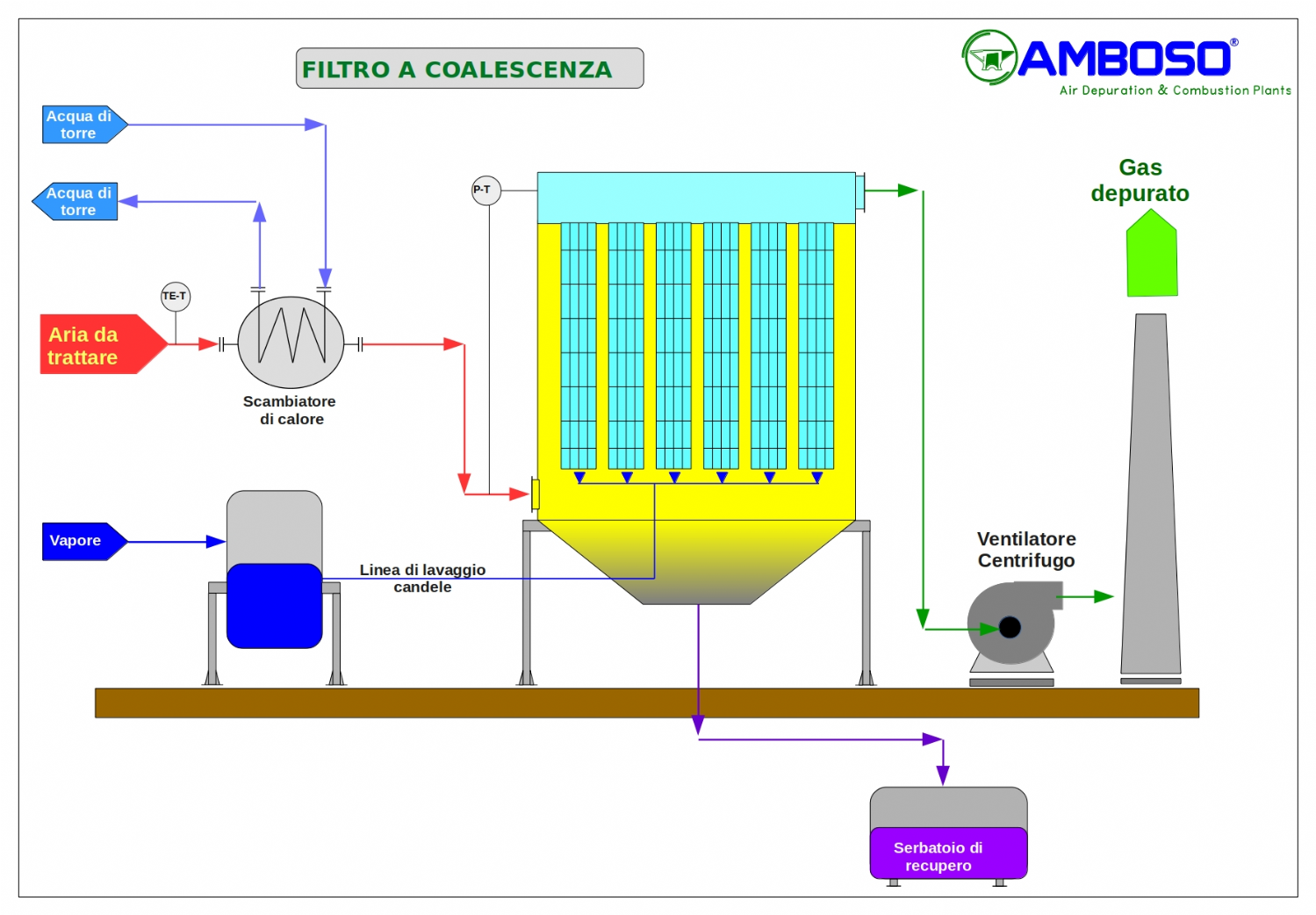

4. Description of the equipment and/or process

The following is the description of an DOP abatement system.

Purpose of this plant is to remove and to recover the DOP present in a given volume of process gases and released (in our specific case) by certain conveyor belt coating and bonding lines during production.

Industry in general often gives rise to process gases containing contaminating substances that are difficult to capture and disposed of. Moreover these fumes may not be discharged freely in the atmosphere. Hence it is also necessary to proceed to clean them in order to reduce the quantity of contaminants to below regulatory limit values or acceptable values for direct reuse in the production cycle.

In this case the above requirement involves considerable investments and running costs which are not always feasible in industries in the small/medium scale.

In the case of DOP, the monodisperse medium par excellence (*), whose physical properties have given rise to one of the current official standards concerned with the determination of the degree of efficiency of almost all the currently produced HEPA filters, the problem of separating its particles from the air is very complex and highly variable depending on its concentration and temperature of the fumes.

There are many well known abatement technologies and widely different equipment which allow these operations based on physical/mechanical principles: absorption, decantation, centrifugation, ultrafiltration etc. – these are only just some of the more widely used methods. However the very best technology is not usually offered by just one of them, rather it is based on a set or union of 2 of them. Furthermore, optimum efficiency of any system is very much based on the need to fully understand the operating conditions to ensure maximum performance and to maintain these conditions. Moreover it is highly important to have a low resistance of the filter medium but at the same time to have a very high collection efficiency.

This is very much case of this plant in particular, whose overall efficiency is given by 2 distinct filtration stages. Hence the reason for the existence of each strictly depends on and is correlated to the presence and continuous efficiency of the other.

A preliminary removal on an inertial cyclonic base with fins takes place before the necessary cooling of the fumes by means of 4 cooling coils whose water temperature is kept under constant control by an evaporating tower. The definitive separation of DOP from the process gas is achieved by using a series of coalescence filter plugs which form the heart of the plant and represent the most reliable means of achieving a collection efficiency equal to or above 99% of DOP present in the air.

Provided the coalescence filter plugs are correctly used, with full observance of the design parameters, they retain their mechanical properties over the long term, they are not subject to deterioration or damage even after heat shocks (within certain limits) while they do not require special maintenance or premature replacement. As the DOP particles have the same dynamic diameter with respect to each other and uniform diffusion, the risk of sudden plugging of the filter medium is practically avoided, with consequent advantage of the pressure drops remaining constant within a sufficient linear spectrum.

The clean air stream is sent towards the stack and discharged into the atmosphere via a silent-running fan installed solely downstream of the system.

Practically all the DOP is recovered and is collected in a suitable tank from which it is returned to the production cycle.

(*) The special characteristic of monodisperse media, of which perhaps DOP is the most representative, is that of including a given quantity of suspended microparticles, with each of the same diameter (dynamic diameter of DOP particle = 0.5 µ)

Equipment used:

- 4 precleaning cyclones

- 2 inertial mist eliminators

- 4 cooling coils

- 2 evaporating towers

- 2 complete systems of coalescence filter plugs

- 2 DOP collecting tanks

- 2 fans

- 1 discharge stack

Operating conditions:

- Overall plant capacity: 60000 Nm3/h

- Fume temperature: 110°C

- DOP content: 350 to 500 mg/m3

- Efficiency: above 99%